5 Key Steps in Worst-Case Circuit Analysis for Reliable Electronics

- Posted On:

- June 11, 2025

- Category:

- Ecad

Imagine your simulated circuit operates without any issues.

The prototype looks flawless.

But, the calamity hits:

The arrival of tolerance-minimum resistors combined with temperature variations exceeding specifications leads to catastrophic failure of your previously “proven” design. Only because of these scenarios, NASA implements 400% safety margins to spacecraft electronics, while medical devices go through harsh environmental stress screening.

The Worst-Case Circuit Analysis (WCCA) provides protection from these imperceptible threats.

It forces the engineers to imagine the extreme negative outcomes and find the possible solution. The WCCA simulation method requires designers to examine all potential failure points using non-textbook assumptions before prototype construction. WCCA provides protection through SPICE simulations which allows designers to strengthen their designs against three hidden threats.

- Component variations (where a 5% resistor tolerance cascades into a 25% system error)

- The simulations typically overlook power anomalies including brownouts and surges as well as ripple.

- Semiconductors lose their predictability under conditions of extreme temperatures.

Engineers face their most severe mistakes when they separate these factors during their work. Systems experience real-world failures when power fluctuations meet operating temperatures that push components beyond their tolerance levels in a combination that simulations rarely forecast. A perfect analogy for this event is a Powerful Storm that was never predicted.

This paper demonstrates how to execute military-grade WCCA through standard SPICE tools utilizing techniques which stopped failures in:

- Automotive systems surviving -40°C to 150°C

- Medical devices achieve precise operations while using aging components.

- Aerospace electronics operating flawlessly with 20% voltage deviations

In this article, we will unveil the limitations of typical “worst-case” analyses while providing methods to generate authentic edge conditions, which distinguish between reliable designs and future operational failures. The difference between theoretical success and practical failure in electronics depends on how hard engineers push their own design to fail. WCCA requires engineers to face and handle all potential deviations including component drift, supply variations, and environmental stresses before the design reaches production phase. Not performing this step will result in expensive product recalls, field failures and safety risks. So, what’s the procedure engineers must follow to conduct an all-encompassing worst-case analysis, which prevents unexpected outcomes? The following five steps guarantee that your electronics will survive extreme real-world operating conditions.

1. Define the Worst-Case Operating Conditions

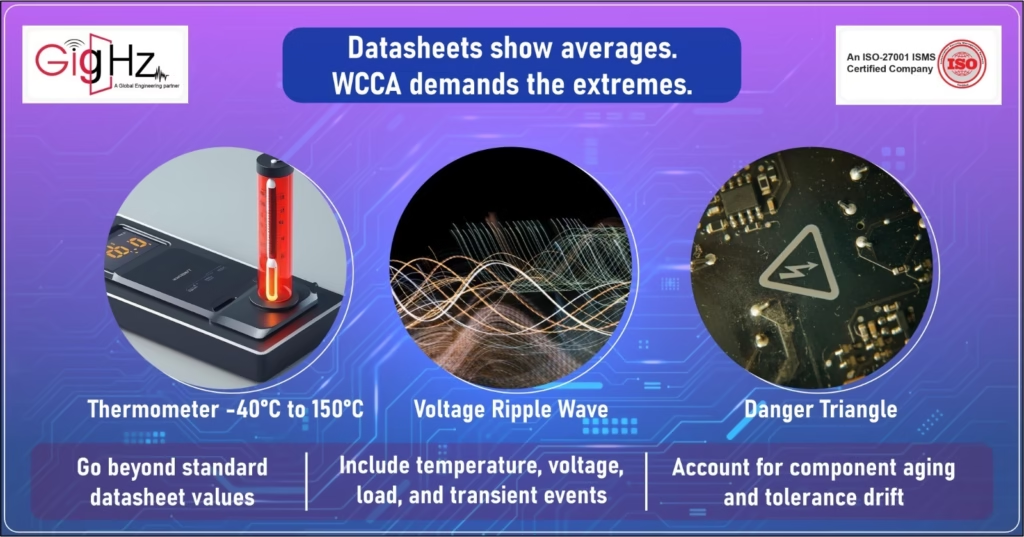

The beginning of worst-case circuit analysis requires designers to establish the most difficult environmental conditions their design must handle. Standard datasheet values alone are insufficient because engineers must predict the real world extreme conditions which could stress a circuit to its maximum.

The first step requires identification of operational boundaries that include temperature ranges, supply voltage fluctuations and load variations. A circuit used in automotive applications must operate between -40°C and +125°C while medical devices need to resist electromagnetic interference (EMI) to maintain performance quality. The analysis should include transient events like power surges, brownouts, and inrush currents since these conditions can exceed steady-state component ratings.

We also need to take into account- component tolerances. The same electrical characteristics do not exist uniformly throughout different manufacturing batches of resistors, capacitors and semiconductors. The 10% tolerance range of resistors appears small at first, but it creates dangerous gain margin changes within feedback networks. Electrolytic capacitors experience a reduction in their capacitance value through both aging effects and temperature changes, thus creating instability in power supplies. The identification of worst-case conditions at the beginning of the process creates a robust analysis framework which examines all potential failure points.

2. Identify Critical Components and Parameters

Worst-case analysis is not required for all circuit components, so identify those which determine performance or safety. Three common electronic components that influence system-wide failure include voltage regulators, precision amplifiers, and timing circuits.

The essential parameters for analog circuits consist of gain together with bandwidth and phase margin. Digital systems require precise monitoring of setup/hold times together with clock skews to operate correctly. The offset voltage of an op-amp shows temperature-dependent variation, which results in incorrect readings for data acquisition sensors. The high temperature increase of a power MOSFET’s on-resistance (RDS(on)) value can initiate thermal runaway.

Passive components serve as essential components for system operation. The power delivery of a DC-DC converter would suffer because an inductor reaches its saturation current limit, while a high-voltage application would experience dielectric breakdown from an inadequately derated ceramic capacitor. Your design becomes stronger by focusing on critical elements because you will not get lost in analysis paralysis, yet maintain protection for your design’s most vulnerable components.

3. Applying Statistical and Deterministic Analysis Methods

Worst-case analysis requires both deterministic fixed-extreme methods and statistical probability-based techniques.

The entire system reaches its maximum tolerance limits at exactly the same time under the deterministic analysis method. The maximum deviation in a voltage divider output occurs when one resistor has +5% tolerance while the other has -5% tolerance, when using resistors with ±5% tolerance. This methodology remains simple, yet proves overly pessimistic because the simultaneous occurrence of component maximum and minimum values remains unlikely.

Monte Carlo simulations and other statistical methods bring realistic outcomes by analyzing probability distributions between variables. Through multiple randomized iterations with tolerance band constraints they determine failure likelihood rates. Using these two methods together provides complete safety information through absolute margins and probabilistic risk predictions.

4. Validate with Corner Case Simulations

The use of simulations remains essential provided they reproduce extreme operational conditions. The circuit undergoes corner case analysis by testing it with various operating condition combinations, which include fast/slow transistors, high/low temperature ranges, and minimum/maximum supply voltages.

The stability of a voltage reference circuit needs to be maintained throughout all PVT (Process, Voltage, and Temperature) conditions. SPICE software enables users to perform parameter sweeps which validate system performance. The output drift of a bandgap reference exceeding 1% at -40°C temperature may require either trimming or implementation of more stable design architecture.

The analysis must include tests for startup surge events, load dump situations, and fault condition scenarios. The survival of a motor driver during normal operation does not guarantee its ability to withstand inductive kickback. Testing the simulated edges in advance allows engineers to detect failures before the prototype development stage.

Real-world validation is equally important. The results from simulations will lead to bench testing under extreme conditions to verify actual circuit performance. This step delivers vital information that links theoretical concepts to actual operational conditions to identify and eliminate any hidden issues.

5. Document and Iterate Based on Findings

Worst-case analysis depends on how well its documentation has been executed. All assumptions together with calculations and simulation results need proper documentation for future reference as well as compliance purposes. Proof of reliability becomes essential for industries under regulation (aerospace, medical, automotive) during audit inspections.

The WCCA report must contain operational constraints alongside component tolerance levels, simulation findings, and planned strategies to address recognized risks. The analysis result showing filter circuit failure at high temperatures requires selection of better capacitors or implementation of thermal compensation.

After documentation the work continues. Analysis reveals weak spots which require you to start an iterative process. The design requires wider margins along with selection of higher-grade components and additional redundancy features. The reliability of the design improves with each redesign cycle, until it reaches an essentially faultless state.

Conclusion: Building Unshakable Electronics with WCCA

The implementation of worst-case circuit analysis becomes mandatory since it distinguishes working prototypes from field-ready electronics. Through systematic definition of extreme conditions, critical component analysis, and deterministic-statistical method integration and simulation validation, and thorough documentation, you will develop electronic goods that resist failure under pressure.

The initial time savings from skipping WCCA prove insufficient because failure expenses from safety issues and reputation damage will surpass all costs. Engineers who excel at worst-case analysis establish confidence through their work because reliability stands as an absolute necessity in current times. When you prepare to simulate a circuit remember to consider the most severe potential outcome first. Your design should be capable of tolerating these conditions.

Eliminate 80% field failure risk by using our WCCA techniques or connect with us, and we can do it for you.

For more updates and WCCA techniques follow us at- https://www.linkedin.com/in/chandra-thimma/

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.