How to Perform Thermal Validation for EV Battery Safety

- Posted On:

- September 19, 2025

- Category:

- Analysis & Simulation

So, that was exactly the statement made by the client in our first meeting.

Basically, an early-stage electric SUV manufacturer had just completed their pilot production.

Now, on paper, all thermal requirements were met.

But during the summer testing in Rajasthan, one battery pack hit critical thermal thresholds within minutes and shut the vehicle completely down.

Likewise, they needed immediate assistance quite fast because they had to submit their report to the potential investor in Singapore.

Now, this is exactly where EV battery thermal validation shows its true worth.

Because spreadsheets don’t melt but battery packs do under extensive loads.

In EV batteries, heat isn’t just cell-generated.

It builds up from I²R heating in busbars, relays, and FETs, compounded by electrochemical reactions inside the cells themselves.

Most lithium-ion chemistries operate safely below 60–65 °C, but once they cross 90 °C, degradation accelerates rapidly.

Beyond 120 °C, the threat of thermal runaway becomes alarmingly real. This is why even a modest 10 °C overshoot can slash a pack’s usable lifespan by half.

That’s why our focus on thermal validation goes beyond simulations—it’s about identifying, measuring, and controlling these heat sources under realistic conditions before they compromise safety, performance, and warranty life.

Hence, here’s a 3-step framework we use to ensure thermal safety in electric vehicles before they hit the road.

Thermal Isn’t Just a Spec! It’s a System Risk.

- Remember, Thermal analysis for EV batteries is not about ticking off simulation reports only. Instead, it’s about understanding how battery heat, ambient temperature, airflow, and enclosure design interact under real conditions..

- Likewise, the OEM in this story had modeled cooling channels, but skipped a full EV battery risk assessment checklist.

- Consequently, it resulted in localized cell heating, uneven dissipations at times and of course, system shutdowns.

What Happens When You Miss the Signs?

So, here’s the problem that early-stage validation often uses conservative test cycles like especially in low load and lab-cooled conditions.

But thermal safety in electric vehicles demands a real testing for:

- Fast-charging under ambient heat

- Regenerative braking load spikes

- Stagnant airflow scenarios (e.g., city traffic)

- Fast-charging under ambient heat

- Thermal runaway propagation risk

And apparently, even if you miss one then your battery doesn’t just become inefficient but unsafe as well.

So, what’s the cost of this? Well, delayed validation and failed regulatory testing. Also damages cells and takes your brand reputation extensively down.

What We Changed for That EV Platform

So, when we stepped in and ran a fresh thermal analysis for EV batteries, this time accounting for full-duty cycle heat soaks. Likewise, our findings shed light into:

- One module was thermally isolated due to bracket placement

- A single vent path caused uneven airflow

- The graphite sheet didn’t make full surface contact

Also, using our EV battery risk assessment checklist, we completed:

- Simulated worst-case fast-charging on incline

- Added phase-change material to edge cells

- Re-engineered vent placement for uniform dissipation

Moreover, within 10 days, pack temperature variation dropped from 14°C to 3.8°C across the array. As a result, we didn’t have any more shutdowns and no more guesswork.

From Reaction to Prevention

Accordingly, this was not just a one-time fix. Likewise, it’s a framework which your team can apply to every EV platform.

So, we that’s how we executed it:

The 3-Step Thermal Validation Framework

Finally, now let us show how we had zero thermal-related recalls in the last 8 critical battery pack programs.

Step 1: Map Every Thermal Flow Path

Now, start by identifying all the sources of heat and not just the cells only. Likewise, it includes:

- FETs, relays, current sensors

- Wire routing zones

- Enclosure wall conduction paths

- Cells exceeding 120 °C enter thermal runaway risk, and designing around “average” temperatures dangerously obscures worst-case hotspots.

Afterwards, simulate dynamic scenarios: sudden acceleration, fast charge and post-brake idles. Accordingly, use this to create a thermal profile map—not just for average, but worst-case hotspots.

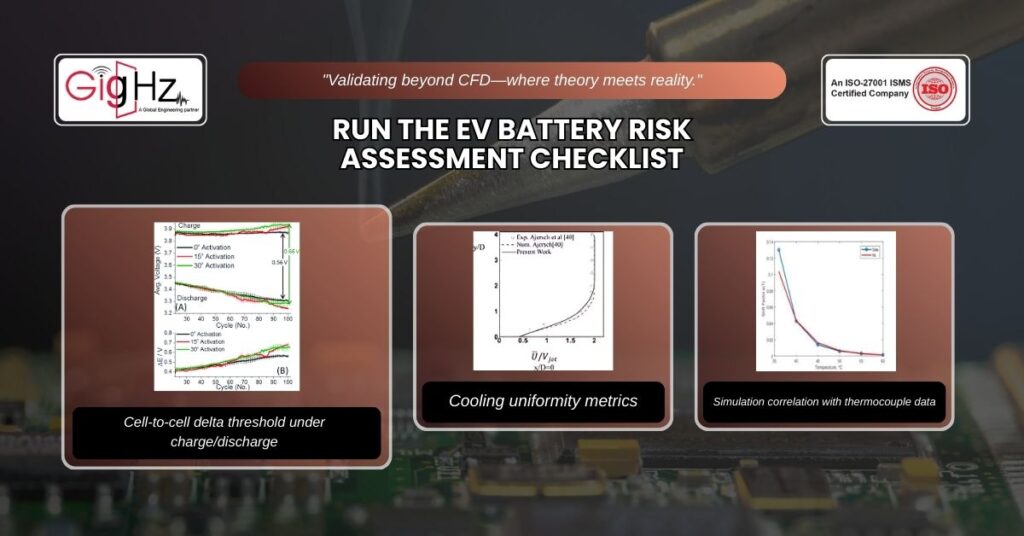

Step 2: Run the EV Battery Risk Assessment Checklist

Then, we also use a custom EV battery risk assessment checklist that includes:

- Cell-to-cell delta threshold under charge/discharge

- Cooling uniformity metrics

- Contact pressure between cells and cooling plates

- Simulation correlation with thermocouple data

- A checklist is only meaningful when backed by numbers—tight ΔT limits, CUF near 1, and proven single-cell containment in runaway tests.

Always, validate every design against measurable limits: keep cell-to-cell ΔT below 5 °C during charge and discharge, pack ΔT within 10 °C of ambient under load, maintain a CUF close to 1 for uniform cooling, and ensure runaway containment so only a single cell fails without propagation.

In addition, this checklist has caught design-level flaws even after CFD signoff.

Step 3: Run the EV Battery Risk Assessment Checklist

Evidently, thermal analysis for EV batteries means nothing unless it reflects the actual use cases.

So, that means testing must showcase:

- High ambient city traffic (low airflow)

- Hill-climb under payload (high draw)

- Post-fast-charge soak periods

Now, here’s the twist: most teams test cell-level and module-level only!

That’s why, we always test the pack in-situ, with enclosure and mounting brackets in place.

Because thermal safety in electric vehicles is not at all modular but also integrated.

For instance, airflow restrictions caused by enclosure geometry, heat retention due to insulation materials, or even thermal bottlenecks around connectors and busbars.

These factors only emerge when the entire pack is tested as a whole, under realistic load and environmental conditions.

By simulating both worst-case and everyday driving profiles, we not only ensure safety margins but also optimize performance longevity.

In the end, it’s not about passing a lab test—it’s about ensuring reliability on the road.

For instance, airflow restrictions caused by enclosure geometry, heat retention due to insulation materials, or even thermal bottlenecks around connectors and busbars.

These factors only emerge when the entire pack is tested as a whole, under realistic load and environmental conditions.

By simulating both worst-case and everyday driving profiles, we not only ensure safety margins but also optimize performance longevity.

In the end, it’s not about passing a lab test—it’s about ensuring reliability on the road.

Bottom Line

Summing up, if your thermal model only runs under ideal airflow conditions and cooling simulations don’t include external loads or solar soaks –

Then, high chances are there that you never correlated simulation with real-world thermocouples

And that’s a gamble no serious company can afford to make it happen.

That’s why, our 3-step validation system blends thermal analysis for EV batteries with real-use simulation and testing.

Which is completely, practical, repeatable and proven.

Want to know if your battery pack is at thermal risk?

Send us your latest simulation vs. test data, and we’ll prepare a 2-page gap analysis — no cost, no strings attached.

Contact us today! For a free consultation at https://gighz.net/contact-us/

Stuck in a loop of challenges? Always pick smart solution that works

Have you faced costly rework because 2D drawings skipped in MCAD workflows?

Effective way to prevent MCAD documentation errors recalls?

Please answer both poll questions before submitting.

Thank you for your response! 😊

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.