Role of MCAD in Product Development

Imagine a world where drawing a picture on a computer screen could turn into real things. That’s what Mechanical Computer-Aided Design, or MCAD, does. It’s like magic for engineers and designers. In this digital adventure, we’ll see how MCAD helps create amazing machines and gadgets. You don’t need to be a genius; you just need a computer and some ideas.

Category :

Published Date :

November 2, 2023

Category :

Published Date :

November 2, 2023

Category :

Published Date :

November 2, 2023

This story isn’t just about machines and computers; it’s about people with big dreams and the tools they use to make those dreams come true. It’s a journey through a world where anything is possible.

So, get ready for a fun ride as we explore MCAD, where drawings become real, and where the future is limited only by what we can dream up.

Below, you’ll find a blog that elaborates on these concepts under the following headings.

- Designing the Blueprint of Tomorrow

- Bridging the Gap Between Imagination and Reality

- A Digital Journey to Product Realization

- Enhancing Collaboration and Efficiency

- Challenges and Future Horizons

- The Rise of MCAD Outsourcing

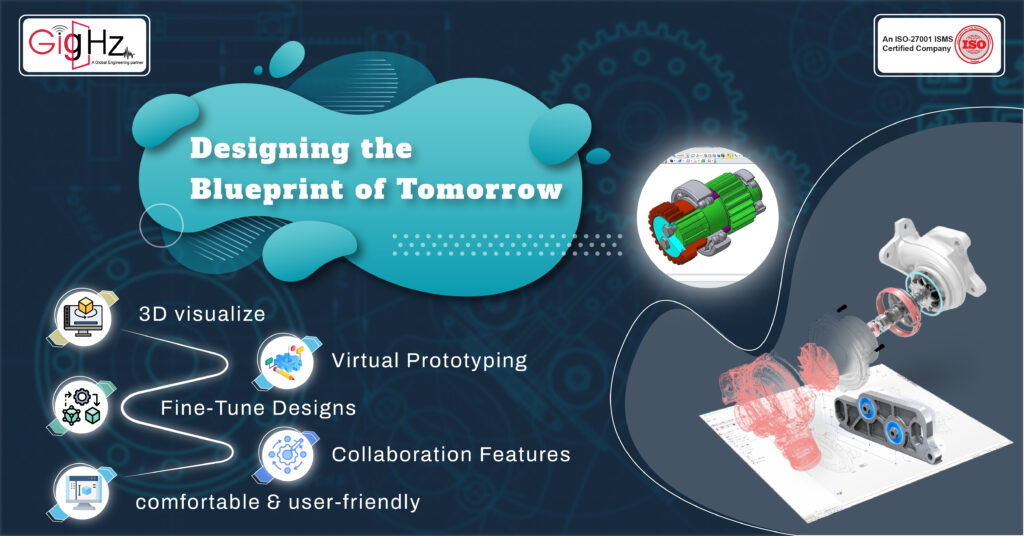

Designing the Blueprint of Tomorrow

MCAD empowers designers to visualize initial concepts in 3D, enabling them to better communicate and refine ideas. It’s a digital canvas where imagination takes form.

Additionally, MCAD’s virtual prototyping allows for cost-effective and rapid testing of design iterations, reducing the need for physical prototypes. It’s innovation without boundaries.

With MCAD, engineers can quickly iterate and fine-tune designs, leading to better products and shorter development cycles. It’s evolution through pixels.

MCAD platforms offer real-time collaboration features, enabling teams worldwide to work seamlessly on a single design. It’s breaking down geographical barriers for creativity.

Furthermore, MCAD tools include ergonomic analysis, ensuring products are not just functional but also comfortable and user-friendly. It’s putting the user at the centre of design evolution.

The Art of Conceptualization:

- MCAD empowers designers to visualize initial concepts in 3D, enabling them to better communicate and refine ideas. It’s a digital canvas where imagination takes form.

Prototyping in the Digital Realm:

- MCAD’s virtual prototyping allows for cost-effective and rapid testing of design iterations, reducing the need for physical prototypes. It’s innovation without boundaries.

Iterative Design Perfection:

- With MCAD, engineers can quickly iterate and fine-tune designs, leading to better products and shorter development cycles. It’s evolution through pixels.

Collaborative Design Environments:

- MCAD platforms offer real-time collaboration features, enabling teams worldwide to work seamlessly on a single design. It’s breaking down geographical barriers for creativity.

Human-Centric Design:

- MCAD tools include ergonomic analysis, ensuring products are not just functional but also comfortable and user-friendly. It’s putting the user at the center of design evolution.

Bridging the Gap Between Imagination and Reality

MCAD’s precision modeling ensures that designs are not only aesthetically appealing but also manufacturable with high accuracy. It’s turning concepts into tangible perfection.

Moreover, MCAD helps in choosing the right materials by providing comprehensive material databases and analysis tools for performance evaluation. It’s the science behind material magic.

MCAD also assists in reducing production costs by optimizing designs for efficient use of materials and manufacturing processes. It’s saving resources without compromising quality.

Additionally, MCAD contributes to sustainability by allowing designers to minimize waste and energy consumption in product design. It’s creating a greener future, one design at a time.

Lastly, MCAD helps ensure that products meet industry regulations and standards, reducing the risk of costly compliance issues. It’s the guardian of quality and compliance.

Precision Engineering:

- MCAD’s precision modeling ensures that designs are not only aesthetically appealing but also manufacturable with high accuracy. It’s turning concepts into tangible perfection.

Material Selection and Analysis:

- MCAD helps in choosing the right materials by providing comprehensive material databases and analysis tools for performance evaluation. It’s the science behind material magic.

Cost Optimization:

- MCAD assists in reducing production costs by optimizing designs for efficient use of materials and manufacturing processes. It’s saving resources without compromising quality.

Sustainability Integration:

- MCAD contributes to sustainability by allowing designers to minimize waste and energy consumption in product design. It’s creating a greener future, one design at a time.

Regulatory Compliance:

- MCAD helps ensure that products meet industry regulations and standards, reducing the risk of costly compliance issues. It’s the guardian of quality and compliance.

Difference Between ECAD and MCAD

The main differences between ECAD (electronic computer-aided design) and MCAD (mechanical computer-aided design) are:

Feature | ECAD | MCAD |

Purpose | Designing electronic systems like circuit boards, ICs | Designing mechanical parts and assemblies like machinery, consumer products, vehicles |

Tools Used | Schematic capture, PCB layout/routing, circuit simulation | 3D modeling, assembly modeling, drafting, finite element analysis |

Design Data | Schematics, PCB files | 3D part and assembly models, 2D drawings, material specs |

Components | Electronic – ICs, resistors, capacitors | Mechanical – machined parts, sheet metal parts, fasteners, springs |

Analysis | Circuit behavior simulation, PCB integrity checks | Stress, dynamic, thermal analysis |

Manufacturing | Produce PCBs and electronic products | Machining, tooling, assembly of mechanical products |

Workflows | Schematic capture, simulation, PCB layout, design rule checks | Part modeling, assembly, drafting, documentation |

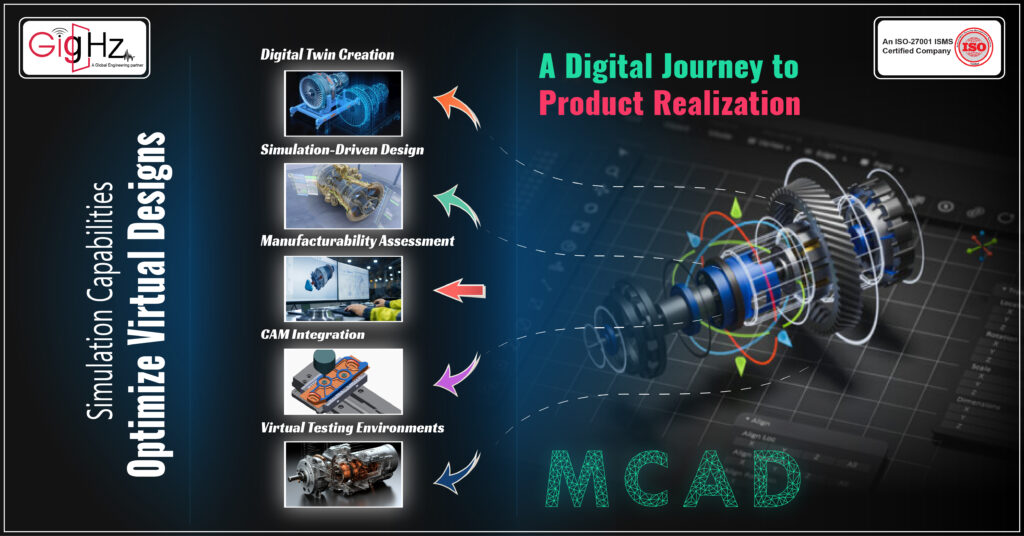

A Digital Journey to Product Realization

MCAD plays a pivotal role in creating digital twins, virtual representations of physical products, for real-time monitoring and analysis. It’s a digital mirror reflecting reality.

MCAD’s simulation capabilities enable engineers to test and optimize designs virtually, reducing physical testing costs and time. It’s test-driving in the virtual realm.

MCAD also identifies potential manufacturing issues early, streamlining the production process and reducing costly revisions. It’s foresight for flawless manufacturing.

MCAD seamlessly integrates with Computer-Aided Manufacturing (CAM) systems, automating CNC machining and 3D printing processes. It’s turning digital designs into tangible products.

Furthermore, MCAD facilitates the creation of virtual testing environments, allowing for comprehensive reliability and performance testing. It’s ensuring products can withstand the real world.

Digital Twin Creation:

- MCAD plays a pivotal role in creating digital twins, virtual representations of physical products, for real-time monitoring and analysis. It’s a digital mirror reflecting reality.

Simulation-Driven Design:

- MCAD’s simulation capabilities enable engineers to test and optimize designs virtually, reducing physical testing costs and time. It’s test-driving in the virtual realm.

Manufacturability Assessment:

- MCAD identifies potential manufacturing issues early, streamlining the production process and reducing costly revisions. It’s foresight for flawless manufacturing.

CAM Integration:

- MCAD seamlessly integrates with Computer-Aided Manufacturing (CAM) systems, automating CNC machining and 3D printing processes. It’s turning digital designs into tangible products.

Virtual Testing Environments:

- MCAD facilitates the creation of virtual testing environments, allowing for comprehensive reliability and performance testing. It’s ensuring products can withstand the real world.

Enhancing Collaboration and Efficiency

MCAD fosters team collaboration by providing real-time access and version control, ensuring everyone is on the same page. It’s teamwork without complications.

Additionally, MCAD streamlines design processes through automation and parametric modelling, reducing repetitive tasks and enhancing efficiency. It’s letting software do the heavy lifting.

Furthermore, MCAD systems efficiently manage design data and integrate with cloud-based platforms, offering accessibility and data security. It’s the freedom of design in the cloud.

MCAD tools enhance project visualization, allowing stakeholders to see the design in action, even before production begins. It’s seeing the future in the present.

Lastly, MCAD software ensures compatibility across various operating systems and devices, making design accessible to all. It’s breaking down technological barriers for creativity.

Team Collaboration and Version Control:

- MCAD fosters team collaboration by providing real-time access and version control, ensuring everyone is on the same page. It’s teamwork without complications.

Design Automation and Parametric Modelling:

- MCAD streamlines design processes through automation and parametric modelling, reducing repetitive tasks and enhancing efficiency. It’s letting software do the heavy lifting.

Data Management and Cloud Integration:

- MCAD systems efficiently manage design data and integrate with cloud-based platforms, offering accessibility and data security. It’s the freedom of design in the cloud.

Project Visualization:

- MCAD tools enhance project visualization, allowing stakeholders to see the design in action, even before production begins. It’s seeing the future in the present.

Cross-Platform Compatibility:

- MCAD software ensures compatibility across various operating systems and devices, making design accessible to all. It’s breaking down technological barriers for creativity.

Challenges and Future Horizons

As we’ve explored the multifaceted role of MCAD (Mechanical Computer-Aided Design) in modern product development, it’s crucial to acknowledge the challenges it faces and the exciting future horizons it’s poised to embrace.

In this segment, we’ll navigate the potential obstacles and promising pathways that lie ahead in the realm of MCAD.

Overcoming MCAD Challenges:

- While MCAD offers remarkable capabilities, challenges such as software complexity and steep learning curves remain. Overcoming these challenges demands continuous education and innovation.

The Rise of Generative Design:

- The advent of generative design, driven by AI and computational algorithms, introduces both opportunities and challenges. Mastering this powerful tool will be pivotal in the MCAD landscape.

AI and MCAD Integration:

- The integration of AI in MCAD presents the potential for design optimization and automation, but it also raises questions about data security and ethical considerations.

MCAD in Sustainable Product Development:

- As sustainability becomes a paramount concern, MCAD must evolve to incorporate eco-friendly practices and materials, posing both a challenge and an opportunity for designers.

Education and Training in MCAD:

- The future of MCAD hinges on a skilled workforce. Addressing the need for comprehensive education and training programs is critical for harnessing MCAD’s full potential.

The Rise of MCAD Outsourcing

Outsourcing in Mechanical Computer-Aided Design (MCAD) has become increasingly common. Many companies now leverage external expertise to reduce costs and speed up project timelines.

By outsourcing MCAD tasks, organizations can access a global pool of talented designers and engineers, ensuring high-quality results.

However, effective communication and project management remain crucial for successful outsourcing in MCAD.

With the right strategies in place, businesses can harness the full potential of this powerful resource and stay competitive in today’s fast-paced engineering landscape.

View the MCAD Services Provided by GigHZ