In the first place, the prototype looked completely flawless!

On the other hand, the 3D models were clean and the assemblies fit perfectly on-screen. Then, in the production stage everything fell apart.

Apparently, the bolts didn’t align, the housings clashed and the parts failed in the QA check as well.

So, what was the reason? Well, of course it was not the design at all. Moreover, The hidden issue was in the subset of MCAD documentation risks specifically, plus with poor or missing 2D drawing standards.

Why do we need 2D Drawings?

So, we all know how current MCAD tools are extremely enhanced and tailored for industry expertise models. Be, it is parametric or visual – It’s tempting to skip drawings altogether at times. But, solely relying on 3D models introduces the scope of dangerous blind spots in your MCAD workflows, for instance:

- Missing or misunderstood tolerances.

- Unclear specs during vendor manufacturing.

- Quality teams unsure what to inspect.

- Assembly rework due to undefined interfaces.

Besides, your model might look perfect, but if 2D drawing standards aren’t applied then your intent will never meet the optimal expectations.

A $700K Lesson

Basically, a high-volume EV supplier once came to us after a costly issue. Clearly, they skipped drawings for a flange that mounted critical modules. Now, the 3D model seemed clear but no tolerance was called out at all!

Also, manufacturing interpreted the flatness extensively differently. And, the result? Well, thermal gaps, failed stress tests and a full rework cycle costing $700K.

Plus, the flaw wasn’t mechanical and it was entirely process-based.

Consequently, this is why every high-reliability team like:

- Automotive

- Aerospace

- Medical

They all need robust MCAD workflows with 2D documentation at the core.

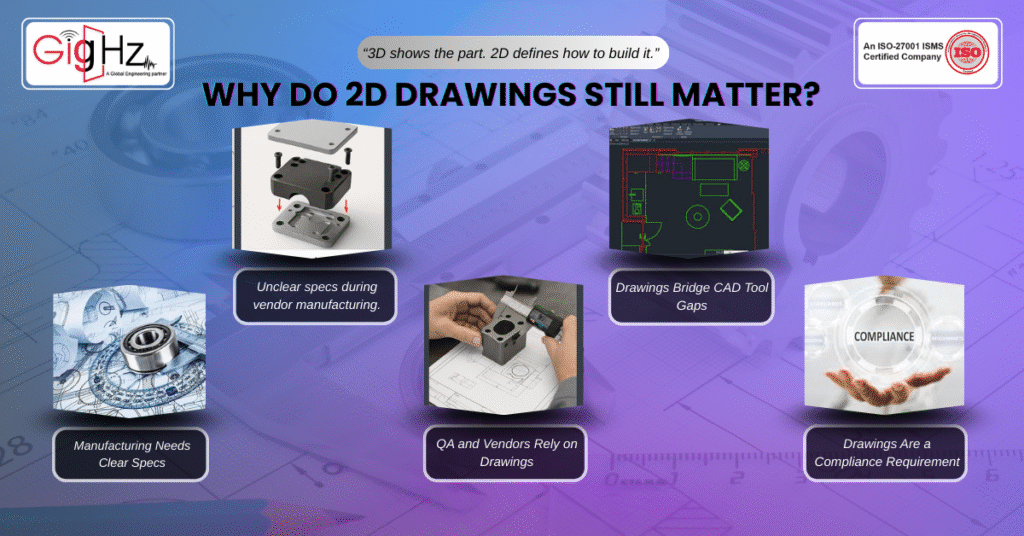

Why Do 2D Drawings Still Matter?

1. Manufacturing Needs Clear Specs

Well, everyone needs more than geometry! Evidently, they need precise and accurate intent.

Hence, 2D drawing standards provide:

- GD&T

- Hole callouts

- Surface finish symbols

- Material and assembly notes

Which 3D files alone don’t deliver all of that to a great extent!

2. Tolerance Stack-Up is Mission-Critical

Now, assemblies with multiple parts suffer from various cumulative variations. That’s why skipping tolerance stack-up analysis risks and may result in fitting issues, stress failures, and dimensional clashes.

Therefore, always emphasizing on proper drawings force engineers to define and check these tolerances early.

3. QA and Vendors Rely on Drawings

So, quality inspection doesn’t work for models! it works from the aspect of specs as well.

Now, here 2D drawings clearly clarify what matters the most, what’s in scope, and what tolerances are acceptable.

For instance, it may turn into something like – Missed specs = failed parts = rework.

4. Drawings Bridge CAD Tool Gaps

Well, not every vendor uses the same 3D platform. So, drawings serve as a universal format which is critical in distributed or offshore manufacturing setups.

Also, well-structured MCAD workflows depend on drawings for cross-team and cross-vendor clarifications.

Beyond being a universal communication tool, drawings also act as the single source of truth when disputes arise between design intent and actual build.

Also, hey capture tolerances, finishes, and assembly instructions in a way 3D models alone cannot.

For distributed teams, especially those working across time zones, drawings eliminate ambiguity and reduce back-and-forth iterations.

In essence, they bridge the gap between design engineering and manufacturing execution—ensuring that every stakeholder interprets the product the same way, regardless of platform.

5. Drawings Are a Compliance Requirement

Finally, for regulated products, 2D drawing standards are not optional at all! Yes, auditors expect full drawing packages with revision history, tolerances, and traceability.

Hence, skipping it may result in failed certifications or worse major recalls.

Quick Fix: Your 5-Step Drawing Reliability Checklist

Likewise, use this as your pre-release check inside your MCAD workflows:

- Include 2D Drawing Generation in the Workflow: Make it part of your release process, not an afterthought.

- Use Standards-Based Templates: Whether it be ASME, ISO, or internal guidelines – pick one and apply it consistently throughout the process.

- Perform Tolerance Stack-Up for Assemblies: Don’t guess! Instead use calculations or tools to evaluate stack-up risk zones.

- Track Drawing Revisions Rigorously: Always, centralize drawing files and tie them to part numbers and releases.

- Learn from NCRs and Vendor Feedback: Consider analysing recurring issues pointing to weak spots in documentation or interpretation.

Bottom Line

Summing up, skipping drawings isn’t a fast process but a very risky one to avoid.

Likewise, skilled MCAD teams always build and make room for 2D drawing standards into their workflows from day one itself.

Truly, 3D modeling covers approximately 90% of the entire design process!

But, it solely cannot close the final 10% required to optimal standards,

Therefore, detailed 2D drawings are always essential and highly needed to bridge that gap.

That’s why, we help engineering teams across industries to upgrade their MCAD workflows with bulletproof 2D documentation.

Likewise, our experts identify the drawing gaps, tolerance stack-up oversights, and compliance weak spots for you – as a result, you get tested templates and smart review flows.

Stuck in a loop of challenges? Always pick smart solution that works

Have you faced costly rework because 2D drawings skipped in MCAD workflows?

Effective way to prevent MCAD documentation errors recalls?

Please answer both poll questions before submitting.

Thank you for your response! 😊

Latest Post

Get Customized Engineering CAD Design Service

Book a Free Consultation Call

Partner with Gighz and bring your most innovative design concepts to life. Our engineering cad services accelerate development so you can focus on your big vision.